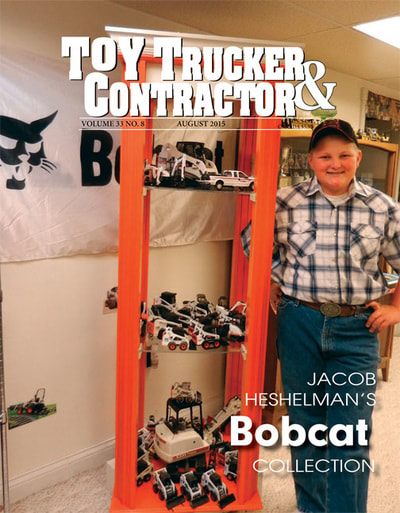

Note: This feature is in the Aug. TT&C 2015 issue.

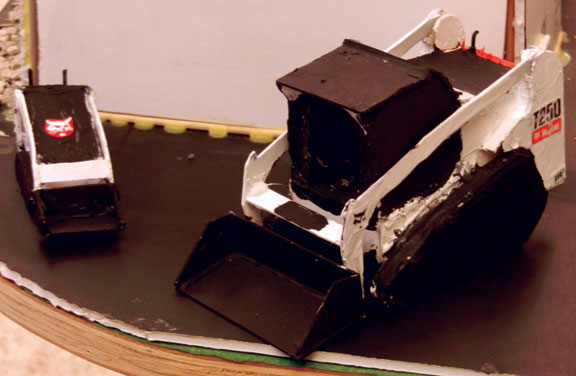

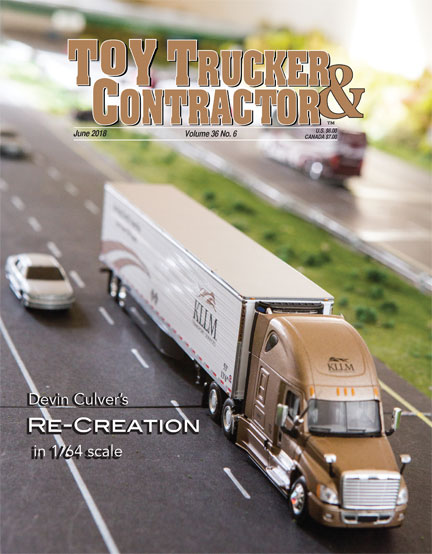

| Jacob, age 2, sits on an 864G Bobcat. He later scratch-built one of these using card stock and hot glue. The large model pictured here is an X331 RC Bobcat excavator, made by Echo Toys Ltd., that is in mint condition. This is one of Jacob’s favorite models. Two of Jacob’s Bobcat models. The smaller one is an M-T55 mini track loader that he scratch-built from card stock. The larger Bobcat is a T-250 compact track loader that was also built out of card stock. Jacob and his father, Ron Heshelman, at the Bobcat factory in Gwinner, N.D. | Jacob Heshelman of Williams, Ind., is a fairly normal teenager. In school, he participated in track, basketball and bowling, and he is eager about entering Mitchell High School, as a freshman, this fall. Perhaps his only unusual behavior is his love of Bobcat model toys. “The first model I remember ever owning was a T-200 Bobcat compact track loader,” the 14-year-old said. “I was very young when my parents bought it for me, and I totally trashed it over time. Most of the models from my childhood met similar fates, but as I’ve begun to seriously collect Bobcat models, I have searched for the models from my childhood. I now have a mint-condition T-200 that I got from the local dealership.” When he was about 10 years old, Jacob became a serious collector. “My first true collectible model was a die-cast T-200 Bobcat compact track loader, made by Ertl, that Dad purchased from Hopf Equipment in Jasper, Ind. This is the model that replaced my childhood model and that whetted my appetite for collecting and customizing models. I began customizing about two years later.” Jacob likes the Bobcat company because it is an American-based manufacturer of farm and construction equipment. The company sells skid steer loaders (what most of us consider Bobcats), compact excavators, compact utility vehicles, compact tractors and other small hydraulic equipment under the Bobcat brand name. It is a major manufacturing company operating in North Dakota. Melroe Manufacturing joined with the Kellers to introduce the four-wheeled M-400 model skid-steer loader in 1960. By 1962, Melroe began using the name “Bobcat” as its trade name for such products. The rest, as they say, is history. In all, Jacob has about 300 models in his collection, with 52 Bobcat models. He also has Bobcat rugs, banners and hats. “I consider the Bobcat advertising part of my model collection, because many of the pieces were given to me and are one-of-a-kind. For example, I have two Bobcat hats that were given to me. Both were custom stitched with Bobcat logos. I’ve never seen any other hats like them. I also have a limited advertising piece that I received from a dealer. It is 1 of 50, made for dealerships only.” Jacob has chosen to ignore scales when choosing a model. He concentrates on detail, quality of the model and the company the model represents. Although he loves Bobcat, he also has Case, Caterpillar and other companies represented in his collection. “I have a large collection of tractors, dump trucks, skid steers and bucket trucks,” Jacob said. “I have a lot of different equipment, and my collection is growing every day. Dad has promised to help me build a new display case in our basement to showcase the collection.” The first model that Jacob customized was a die-cast T-770 Bobcat compact track loader (manufactured under a Bobcat licensing agreement). “I put on a complete forestry package with a forestry mulcher head. I had seen the real machine in operation and thought it was a neat piece of equipment. When I looked for a model of it, I discovered there weren’t any, so I customized my own. I added guards to the cab, a front door, a back window, guards on the lights and hydraulics, and, of course, the forestry mulcher head.” Not only was the T-770 Jacob’s first customizing job, it has proven to be his most difficult. “The T-770 forestry cutter is a detailed piece of equipment,” Jacob said. “It has safety glass, air intake covers and hydraulic guards. The hydraulic hoses are very small, and I have big hands, so it was hard for me to install the hoses on the cutting head. Also, cutting the foam and shaping it for the cutting head was difficult because it needed to be shaped in such a way that the blades could be easily attached. I guess customizing my most difficult model first trained me to take on harder customizing jobs.” In school, Jacob participated in shop class, but “shop class did not help me much,” he said. “Most of my customizing has been self-taught, using my own tools at home and using Dad’s tools when he is out of town.” Want to read the rest of the story? It's available in the AUGUST TT&C 2015 magazine! Download here: AUGUST TT&C 2015 Call (701) 883-5206 or (701) 883-5206 to purchase or order online at: http://www.toytrucker.com/past-issues.html |

RSS Feed

RSS Feed